My Store

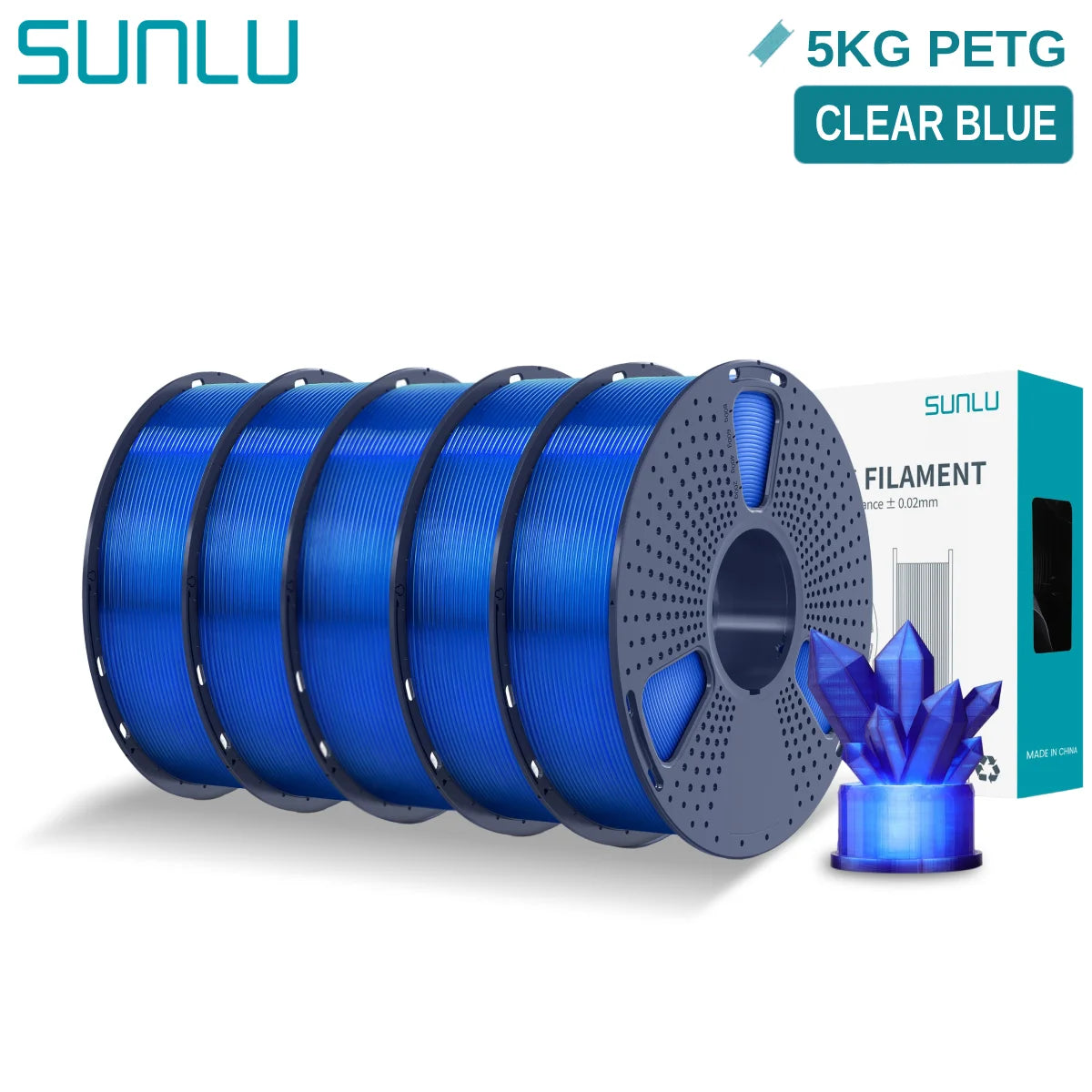

SUNLU 5KG PETG 3D Filament 1.75mm Neatly Wound High Toughness 3D Printing Spool Filament for FDM 3D Printer Materials Fast Ship

SUNLU 5KG PETG 3D Filament 1.75mm Neatly Wound High Toughness 3D Printing Spool Filament for FDM 3D Printer Materials Fast Ship

Couldn't load pickup availability

SPECIFICATIONS

Advantages: 100% no bubble

Brand Name: SUNLU

Bubble: no bubble

Certificate: RoHS , Reach

Diameter: 1.75mm

Form: Solid

Hign-concerned Chemical: None

Material: Other

Model Number: PETG Filament

Name: SUNLU 5KG PETG 3D Filaments

Origin: Mainland China

Print Temp: 230-250 degree C

Print speed: 30-50mm/s

Size: 335 meters

Tolerance: +-0.02MM

Warranty: one-year

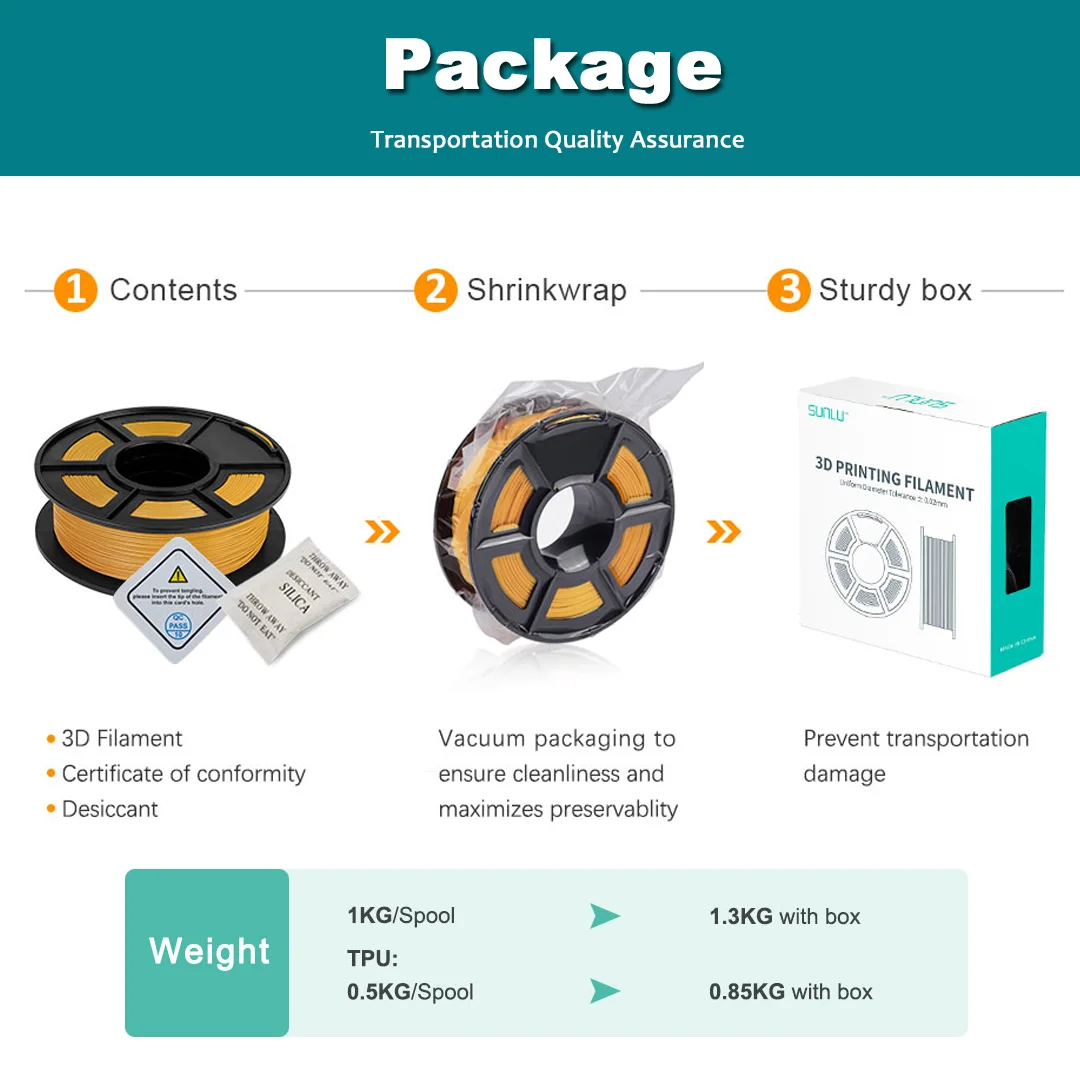

Weight: 1.3kg /roll

Wire diameter: 1.75MM

Tolerance: ±0.02MM

Printing temperature: 230-240℃

Haet bed temperature:60-70℃

Bottom plate temperature: glue is required when not heated. Glue is not required for heating 60-80℃

Tension (KGF): 8-14

Melt index: 6-11g/10min (220℃, 2.16kg)

Elongation at break: 210%

Print speed: 40-60MM/s

Bubbles: 100% zero bubbles

Net weight: 1KG/roll

Gross weight: 1.3KG/roll

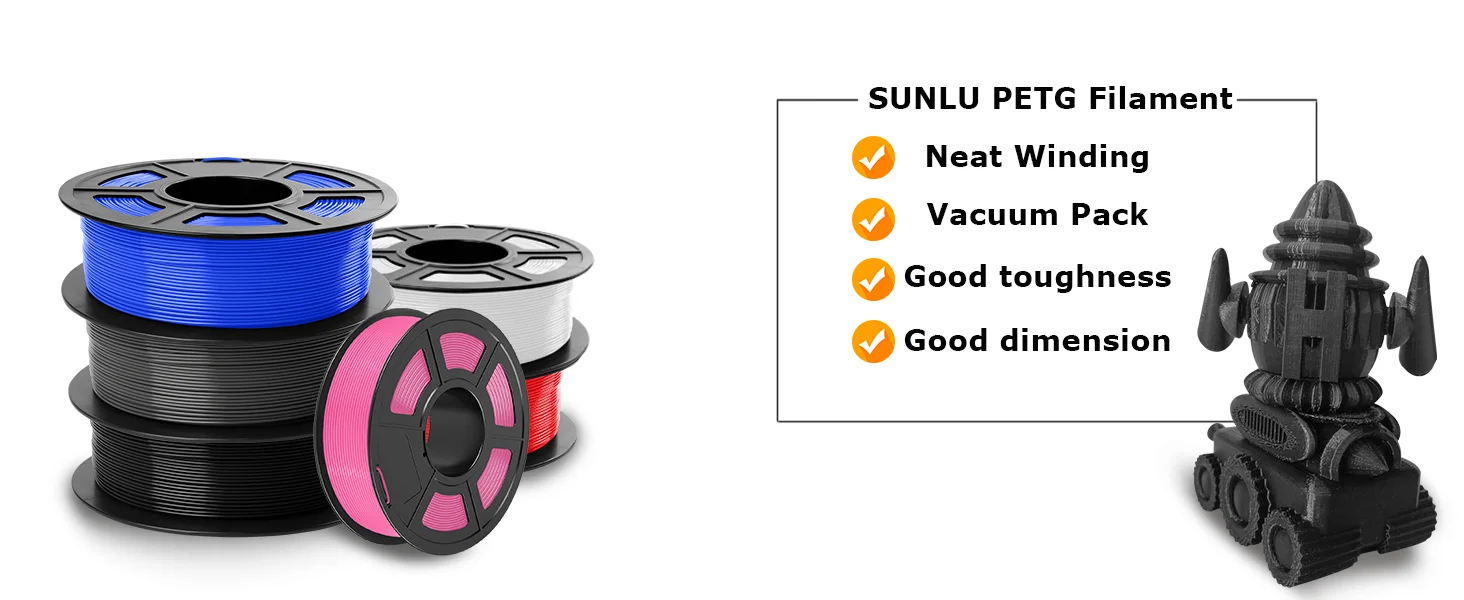

Features

1.Environmental protection and non-toxic;

2. Bright color;

3. Low shrinkage;

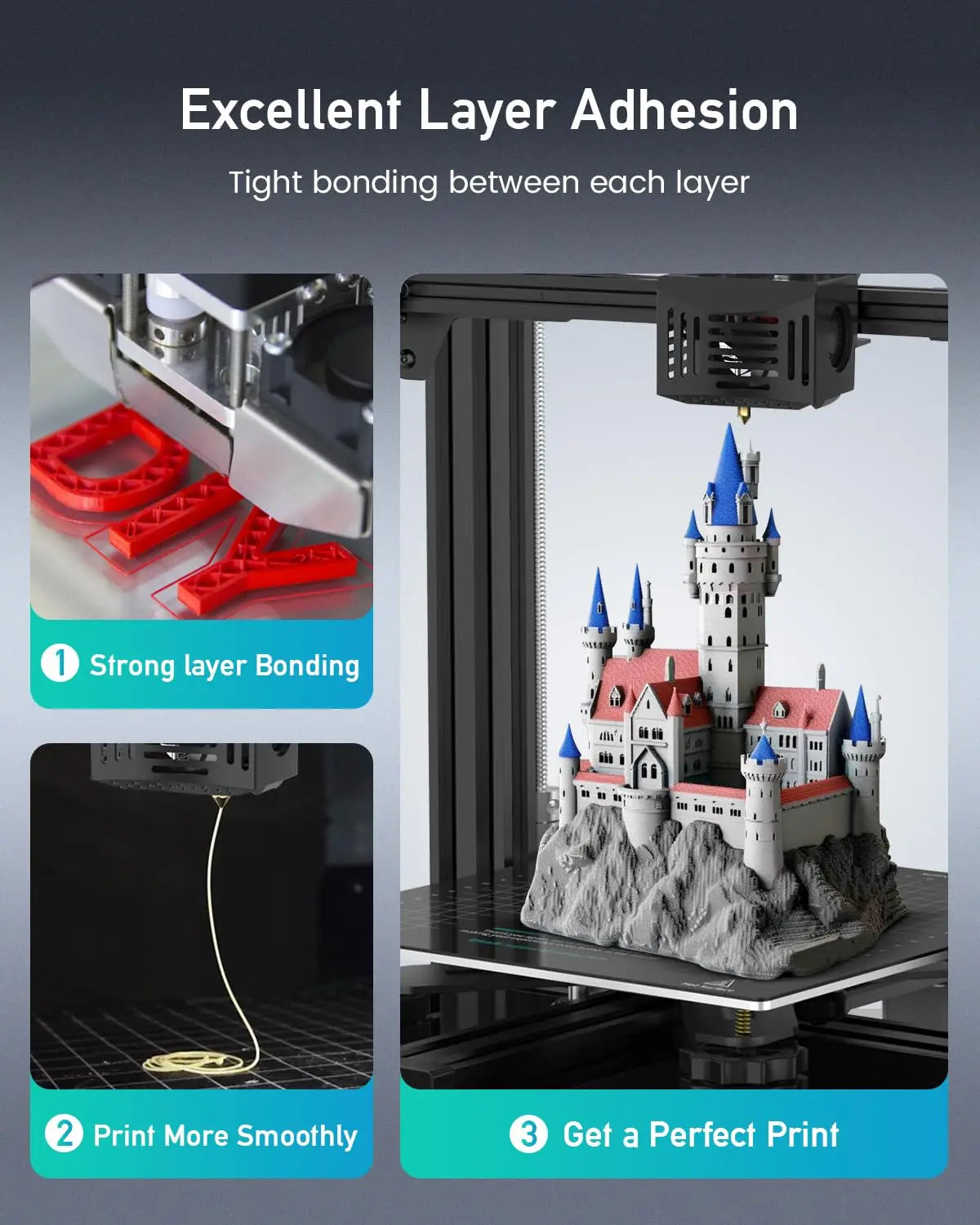

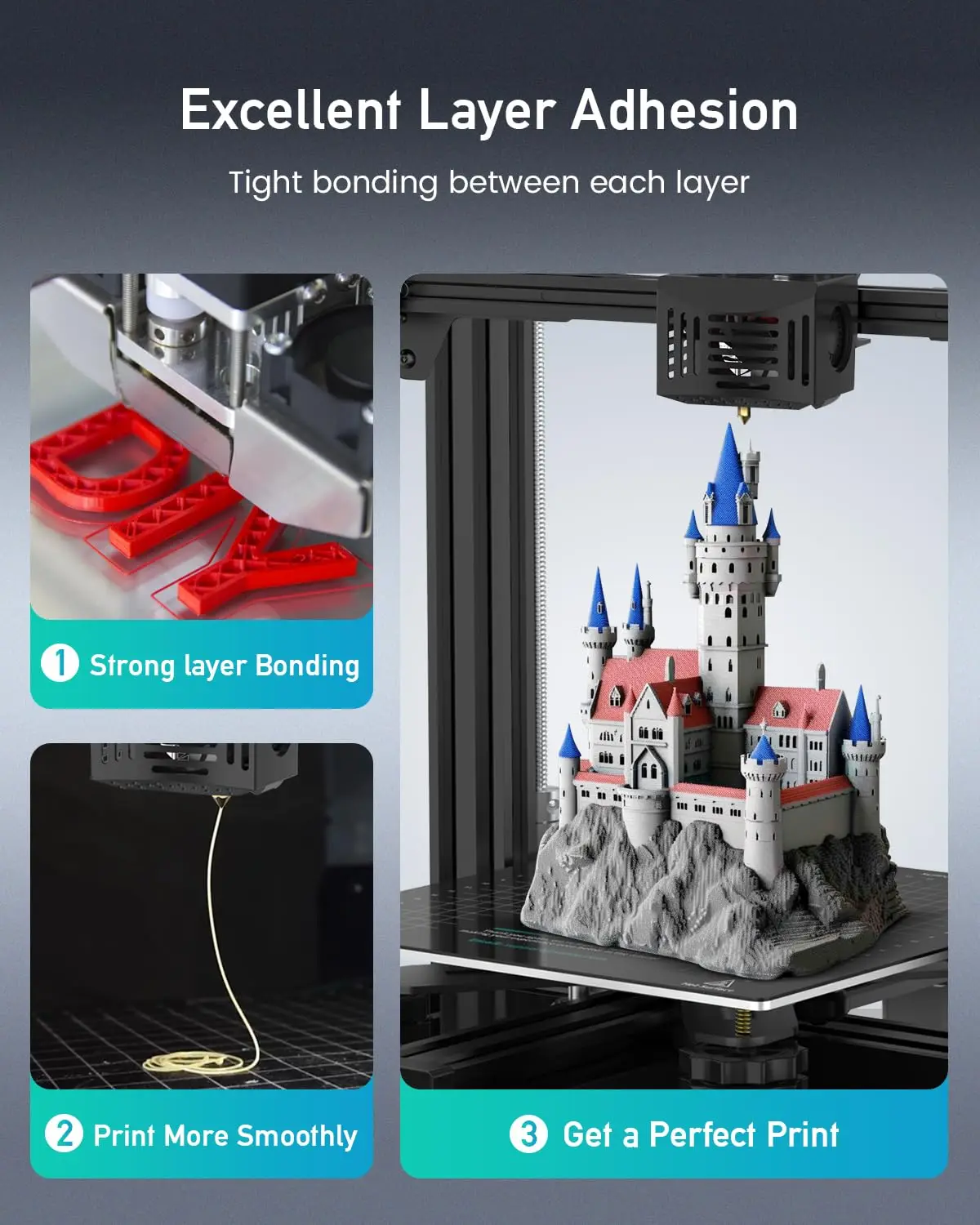

4. Good toughness, not easy to be brittle, good acid and alkali resistance, excellent toughness, weather resistance and good adhesion.

5. Good dimensional stability, without cracks and warpage.

6. High transparency and good gloss.

It is suitable for all types of FDM3D printers, suitable for printing all kinds of commonly used models, crafts, industrial parts, advertising words, etc.

PRODUCT PACKAGE

Print Works

About SUNLU

CERTIFICATE

Estimated Delivery Time

* Oversea warehouse about 3-7days;

* China shipment about 18-35days, If you buy up to 10 rolls, we will send you fast shipping.

SHIPPING

* You can check any tracking number through this website: https://www.17track.net/zh-cn,or just leave message to us,then we will check the tracking number for you. * We will ship your order in 1-4 bussiness days,and provide tracking number as soon as possible.

CONTACT US

* If you do not receive the goods within the estimated time,or there are any problems with the goods,please feel free to contact us,we will refund you or send you the goods agian for free. * We have a factory,which means we will continue to offer preferential prices and high quality products,and we will provide pre-sales and after-sales service, so do not worry about any after-sales problems.

SUNLU 3D Printing Troubleshooting Guide

* Issue 1: Filament Surface Defects (Notches/Damage)

Root Cause: Physical damage during production or transportation.

Solution:

1. Immediately stop printing. Check the remaining filament on the spool for defects.

2. Contact SUNLU Support: Provide clear photos of the damaged section for replacement.

* Issue 2: Uneven Model Edges

Root Cause: Inconsistent extrusion due to filament diameter variation or moisture.

Solution:

1. Measure Filament Diameter:

Extract 1-meter filament and use calipers.

Gently clamp the filament at the center of the calipers (avoid excessive force).

Tolerance range: 1.75mm ±0.02mm.

Dry Filament: Use a filament dryer at 45-50°C for 4-6 hours if moisture bubbles are observed.

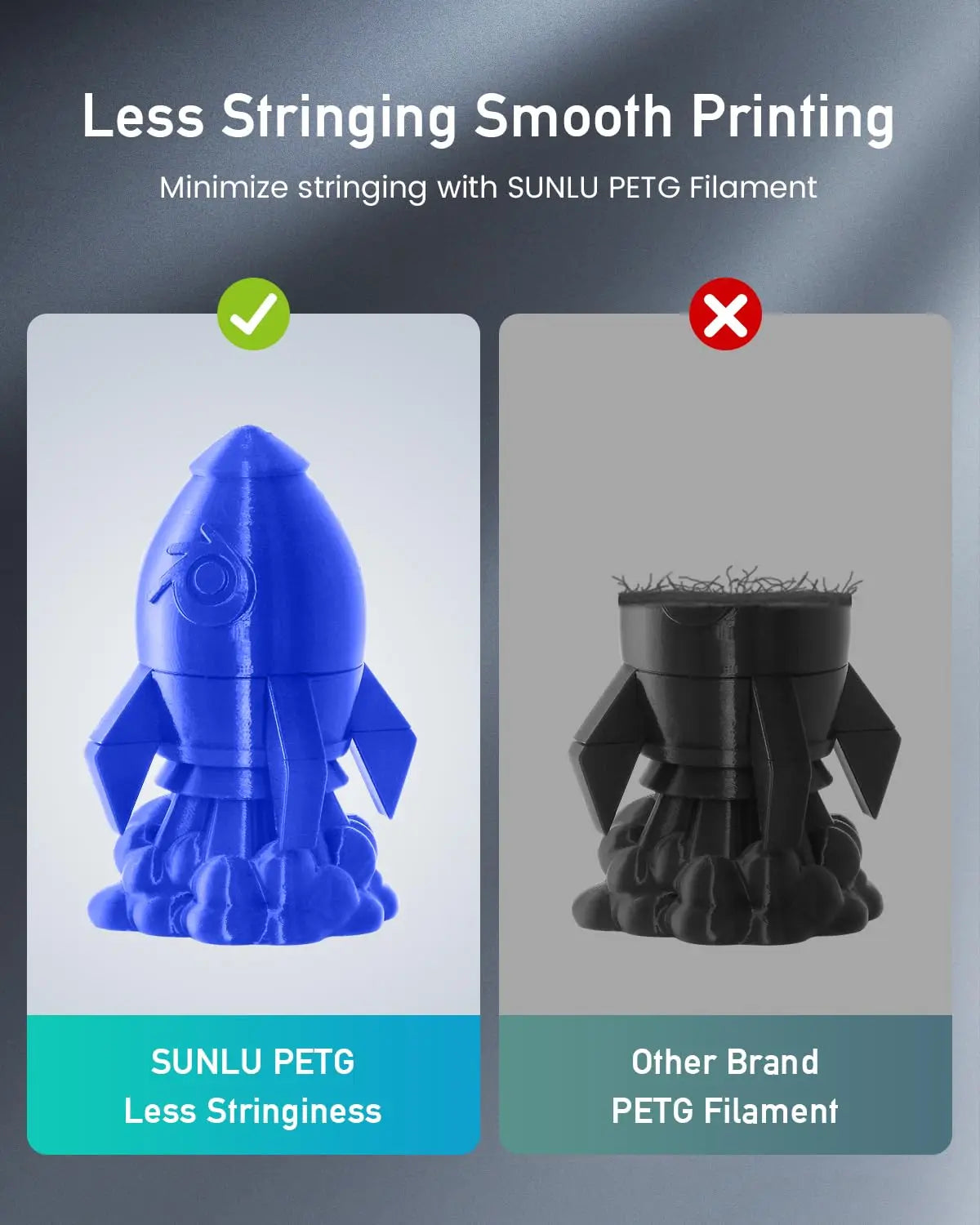

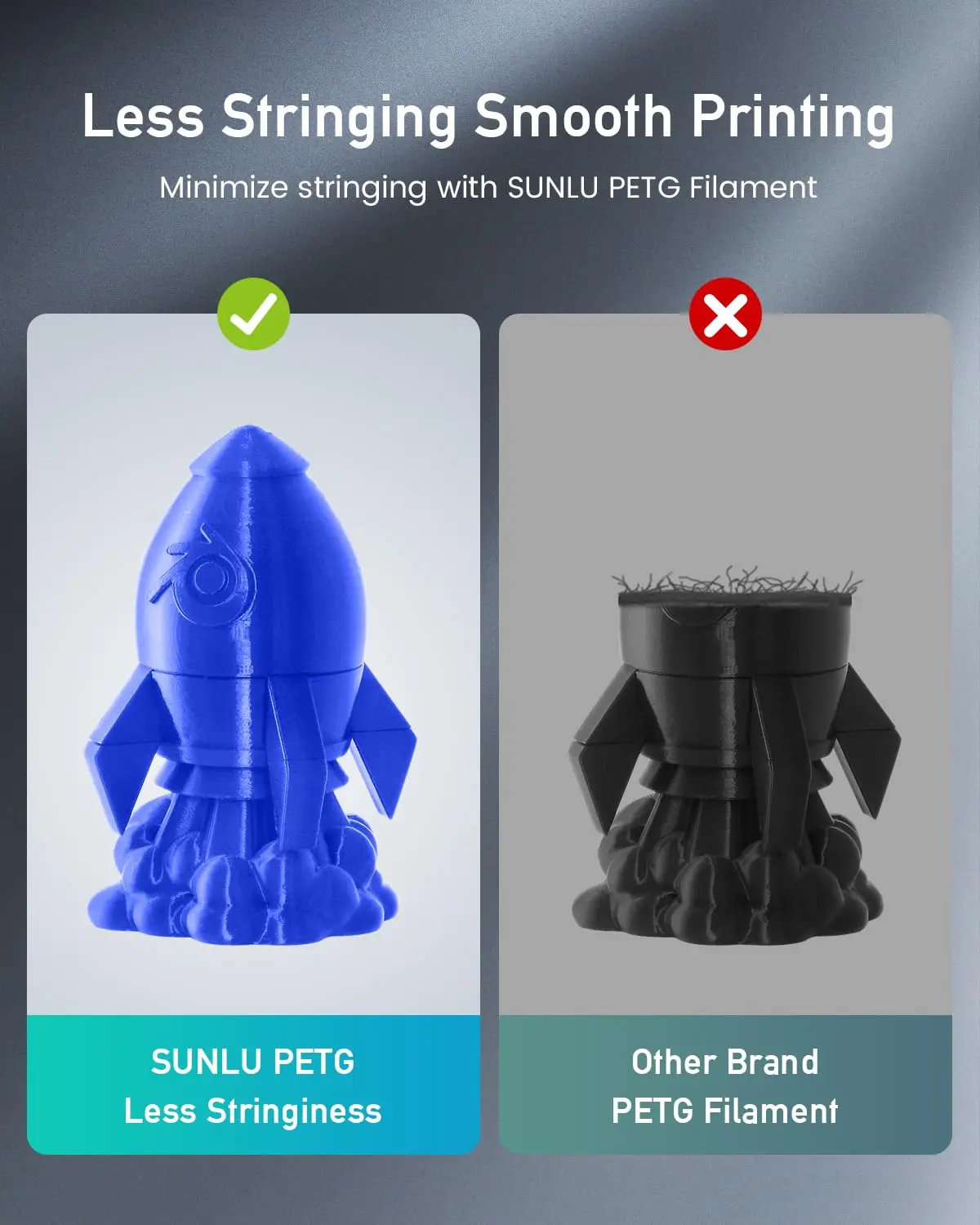

* Issue 3: Stringing/Oozing

Root Cause: Insufficient retraction, high nozzle temperature, or damp filament.

Solution:

1.Retraction Calibration:

Start with default settings: Retraction distance 5mm, speed 40mm/s.

Adjust within 20-100mm/s range through iterative testing.

2.Temperature Optimization: Reduce nozzle temperature by 5-10°C if stringing persists.

* Issue 4: Filament Tangling

Root Cause: Improper storage or reloading of partially used spools.

Solution:

Locate the tangled section and carefully unwind it.

Preventive Measure: Always secure filament ends using the SUNLU filament clip or thread through the spool hole after use.

* Issue 5: Poor Bed Adhesion

Root Cause: Incorrect nozzle height, low bed temperature, or rapid cooling.

Solution:

Nozzle Height Calibration: Adjust to A4 paper thickness between nozzle and bed.

Temperature Adjustment:

Increase bed temperature (e.g., PLA: 60°C, PETG: 70°C).

Apply SUNLU bed adhesive or enable "Raft" in slicing software.

* Issue 6: Brittle Filament

Root Cause: Over-drying (>48hrs at high temps) or factory defects.

Solution:

For over-dried filament: Store in sealed bags with desiccant.

Contact SUNLU Support if brittleness occurs immediately after unsealing.

Root Cause: Lighting variations or minor batch differences.

Solution:

Compare under 6500K white LED light (industry standard).

Note: Natural color variations within ±5% are normal.

Share